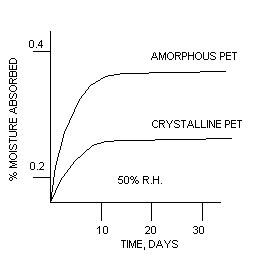

Moisture Absorption

The amount of moisture absorption depends on various factors like time, temperature, atmospheric humidity (dew point) and the crystallinity of the chip. PET in Amorphous form absorbs moisture more rapidly than in crystalline form. The high level of crystallinity in RELPET (>50%) helps in slower moisture absorption rate. Picture on right shows typical rate of moisture absorption by PET.

Why to Dry PET before processing?

During plasticising in the extruder, presence of moisture breaks polymer chains leading to reduction in the molecular weight i.e. drop in IV. This will effect final container properties. Drop in IV makes the melt fluid (runnier), so the injection flow control, wall thickness distribution becomes difficult during preform moulding. Lower IV resins also crystallize faster than higher IV ones resulting in hazy/milky appearance.

During plasticising in the extruder, presence of moisture breaks polymer chains leading to reduction in the molecular weight i.e. drop in IV. This will effect final container properties. Drop in IV makes the melt fluid (runnier), so the injection flow control, wall thickness distribution becomes difficult during preform moulding. Lower IV resins also crystallize faster than higher IV ones resulting in hazy/milky appearance.

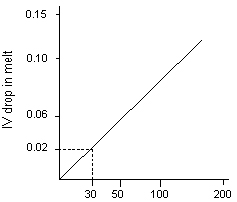

To obtain maximum product performance, it is essential to reduce the moisture content to less than

To achieve proper drying of PET recommended drying temperature is in the range of 150 ~ 180°C. Amorphous PET exhibits Tg (Glass transition temperature) around 80°C while the crystalline PET is almost nearer to the melting point. Because of this, crystalline PET can withstand the recommended drying temperatures, the amorphous PET tends to soften and form agglomerates at around 80°C. The difference in the behavior of crystalline PET and amorphous PET during drying should be well understood. RELPET chips are supplied with high level of crystallinity (>50%) which ensure trouble free drying. Dried PET will re- absorb moisture very rapidly if exposed to the atmosphere. Hence, it is essential to arrange direct entry of material into feed throat from the hopper to avoid atmospheric contact of dried material.0.004% (40 parts per million), or preferably about 30ppm prior to melting. Excessive drying temperatures also can lead to thermal and oxidative degradation. Picture on the left shows typical values of IV drop due to retained moisture in the

PET during processing.

Moisture Removal - The Diffusion Process

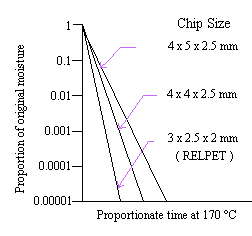

The moisture, which is entrapped in the resin, will diffuse towards the center of the PET chip. Due to this, PET drying is different from other drying processes where surface moisture removal alone is the target. Because of this diffusion phenomenon, relatively long drying times and hot dry air are primary requirements. The drying time depends on size of the chip. Smaller the size, faster is the drying.

Figure on the right indicates the relative time difference with different chip sizes, for achieving required level of dryness.

De-Humidifying Dryer:

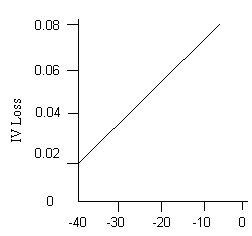

These types of dryers circulate hot and de-humidified dry air onto the resin, suck the air back, dry it and then pump again in a closed loop operation. This process reduces moisture level in the PET down to 40ppm or lower. The efficiency of moisture removal depends on the air dew point. If the air dew point is not good, then some moisture remains is the chips and cause IV loss during processing. The graph on the left shows typical values of IV loss associated with different air dew points.

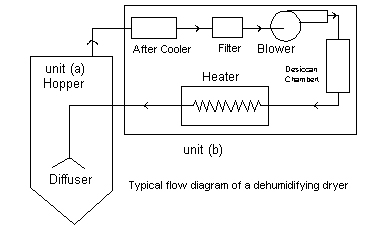

Dryer consists of two major parts:

(a) Hopper: Material that needs to be dried is placed in this. There are two common methods of connecting this to injection unit. Either directly fixing this over the injection unit, or placing this on a stand and connecting the hopper exit to the barrel with a flexible high temperature withstanding hose.

(b)Drying unit: This is housed in a separate cabinet nearer to the hopper.

The only connection between both the units is flexible hoses, which can with stand high temperatures. These hoses are used for carrying dry and return air. The following picture shows a typical flow chart of dehumidifying operation

The air first comes into contact with the material through the diffuser,which is attached at the lower portion of the hopper. Diffuser spreads the air across the entire cross section of the hopper. Most hoppers will have a converging bottom as well as an internal distribution cone, to ensure plug flow of the chips through the system. The dry- air then passes upward and reenters the drying unit after passing through the after cooler and filter. This closed loop operation makes this an efficient drying process. The air dryer is designed to remove moisture from the return air and to re-circulate.First,the air is cooled down in a heat exchanger to around 40 °C and then passed through a filter

to remove any fines, which are carried by the return air. The performance of the desiccant depends on the inlet air temperature; hence, cooling the return air is very important. This air is then passed through a desiccant bed to remove the moisture in the air. The desiccant bed contains pellets or granules that absorb moisture and are known as molecular sieves.

Regeneration:

Once the desiccant reaches saturation level, it can no longer absorb any moisture. The operation of expelling moisture from the desiccant and drying it is called regeneration. Air heated up to 290°C is passed through the desiccant bed causing the desiccant to give up the moisture which was absorbed during drying, and this moisture is flushed out of the system through air. The air is heated by a separate heating system than the one used for the drying process. In an efficient system the drying operation and regeneration operations are carried out independently. This is made possible by providing two separate blowers one for drying and the other for regeneration and also, the desiccant is arranged either in two interchangingcolumns or in four columns fixed on a rotating. This helps in uninterrupted drying operation during regeneration. There are also economic systems available in which the same drying blower is used for regeneration. In this system, the drying capacity

reduces due to interruption in drying during regeneration.

Normally, all these systems are fitted with an auto loader on top of the hopper to maintain chips level in the hopper. A thermocouple to control air temperature is also attached at the air entry point to the hopper. A high temperature protection device is important to protect the material in the hopper from fusing together.

Key Parameters to achieve efficient drying

1. Chip temperature: The actual chip temperature measured at the dryer exit point should be around175°C.

2. Air temperature: Drying air temperature is measured at the inlet to the dryer and this shouldn’t exceed 190 to 200°C.

3. Air dew point: This should preferably be at -40°C or lower measured at the air inlet to the dryer. It shouldn’t be allowed to rise above -30°C.

4. Air flow: Adequate airflow must be maintained across the bed. Although various equipment suppliers used different airflow rates, minimum flow rate of 3.8m3/kg/hr must be maintained across the material.

5. Chip residence time (drying time): Minimum 4 hours preferably 6 hours. Resident time is calculated by dividing weight of material (kg) which can be filled in the hopper, by resin throughput (kg/hr).

Tips on up-keeping the dryer for better performance:

1. Air filter: Routine filter cleaning of both drying and re-generative filters is essential.

The filter protects the desiccant beds from dust. Great care must be taken not to damage

the filter. Bad filter reduces airflow and effects drying. Replacement of filters must be

according to original specification only.

2. Heat Exchanger: Due to blockages and scaling heat exchangers lose efficiency. This

effects the efficiency of drying. Maintenance as per the manufacturer’s recommendation

should be carried.

3. Heater failure: Failure of heaters main/regeneration can lead to either inability to achieve the correct drying temperature and/or the inability to achieve the correct desiccant bed regeneration temperatures. It is required to ensure proper functioning of heaters, electrical contactors and temperature controllers by frequent checking.

Note: The set point temperature continues to indicate even with one of the defective heating elements because the heater may contain multiple heating elements. It is essential to check the heaters periodically, because, the hot air looses its heat as soon as it touches the material. If there is a temperature indicator to indicate chip temperature at the feed throat, then it is possible to identify this before hand.

4. Auto Loader: Clean dust collection bags and check loader operation/level sensors regularly.

5. Ingress of ambient air: Ambient air is very wet compared to the drying air. If any ambient air enters the drying system that will adversely affect the dew point and hence drying efficiency. It is important to check periodically, for any air leaks inside the dryer cabinet and outside. Loose or damaged hoses are some of the root causes of this.

6. Repairs: Replace the parts removed for maintenance with appropriate gaskets and sealant and test for leaks.

7. Process control of dryer: Monitor dry air temperature and dew point. (Dew point indicator is optional equipment in most dryers).

It is a good practice to crosscheck all temperatures using a calibrated digital thermometer attached with a suitable probe. The dew point should be measured once in six months or as and when a maintenance work is undertaken. Monitor the airflow through the dryer.

Drying of Recycled PET

Normally recycled PET is in amorphous form, which is clear unless other wised

crystallized. This can result in processing problems because it clumps when dried at

normal drying temperatures (175°C). So amorphous flake has to be recrystallised before it

is dried. In most practical situations, a minor addition of factory reground of rejected

preforms/bottles doesn’t give problems. The addition levels depend on process.

Conclusion

Drying is the most critical step in PET processing. Failure in meeting the correct drying criteria cannot be corrected in subsequent moulding operation.

Understanding important parameters:

Dew point: Dryness of air is measured in dew point. The temperature at which water vapor from the air begins to form droplets and condenses on surfaces that are colder than the dew point of the air. It is expressed in ºF or ºC. Lower the dew point, higher is the dryness of air.

Relative Humidity: It is the ratio of the amount of moisture in the air to the maximum amount of moisture the air can hold at the same temperature and pressure. For e.g. if RH is 100%, then the air can’t hold any more water and if RH is 0% air is totally dry. RH is a function of temperature and warmer the air, more moisture it can hold.

Intrinsic Viscosity (IV): IV is a measure of the average molecular weight. It denotes the average length of molecular chain. Products moulded from higher IV material will have higher mechanical strength compared to products moulded from lower IV material. Molecular weight and IV are interrelated to each other.

Copy From Reliance Industries Limited (PET BUSINESS CROUP)

CHINESE

CHINESE ENGLISH

ENGLISH