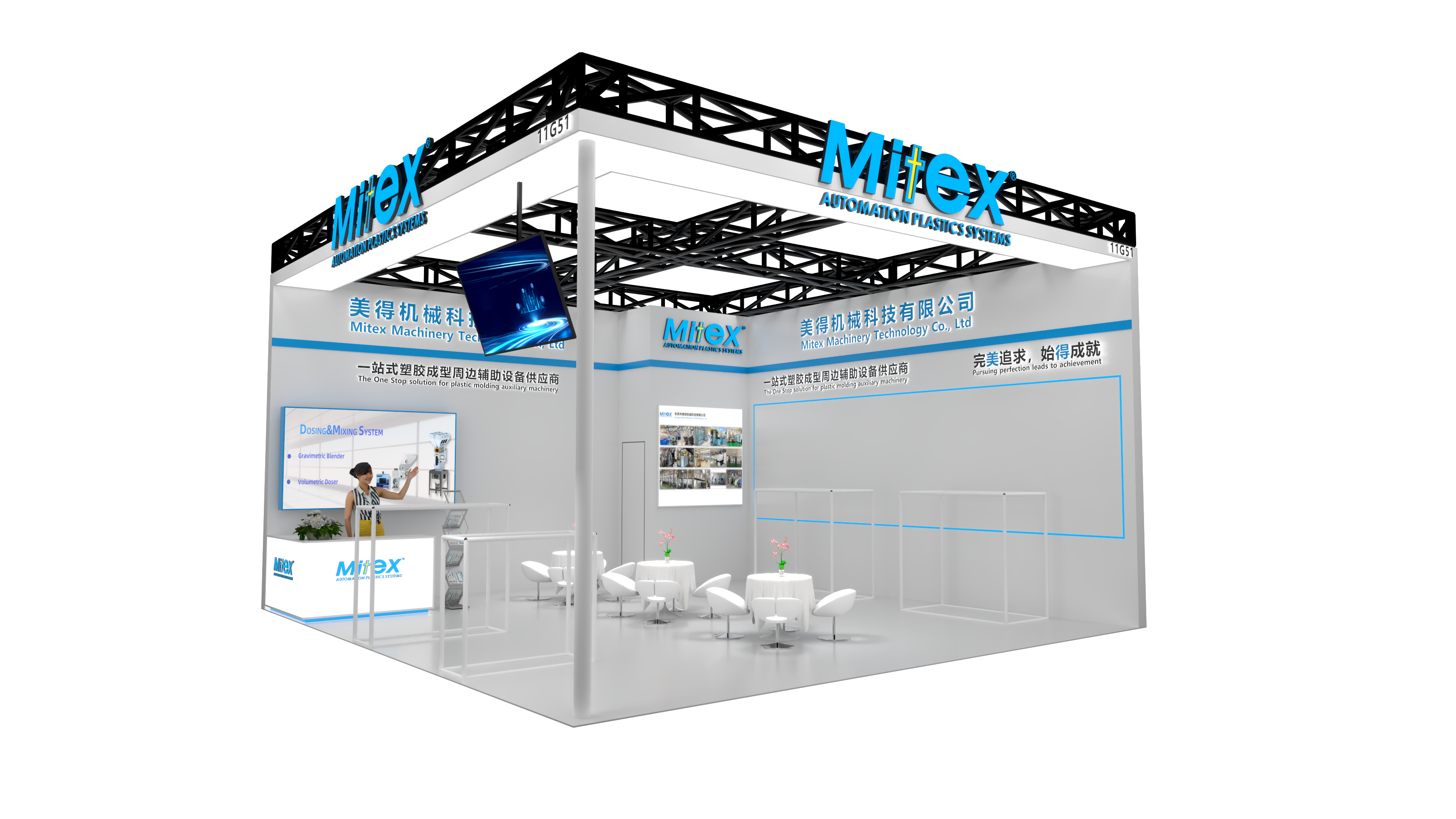

You are warmly welcome to our booth 11G51

One of the most important and critical factors in the processing of PET is that the material should be nearly free from moisture to avoid processing problems and defects in the finished products such as haziness, voids, sliver streaks, streaks and also to derive better physical/mechanical properties.

The transformation process of plastic materials by injection molding represents a very widespread technology adopted in many business sectors. In most cases this process is employed in the production of technical parts also used in the medical and aerospace industries.

Films for packaging, sheets for water, plastic profiles, cables are indispensable objects in our lives. Extrusion is the process that transforms the majority of plastic materials in the world. No burrs are admissible in the processes:

The path travelled by water from its source to the consumer crosses through packaging, and in other words the PET bottle: absolute rigour is required in the production of bottles holding this highly precious good.